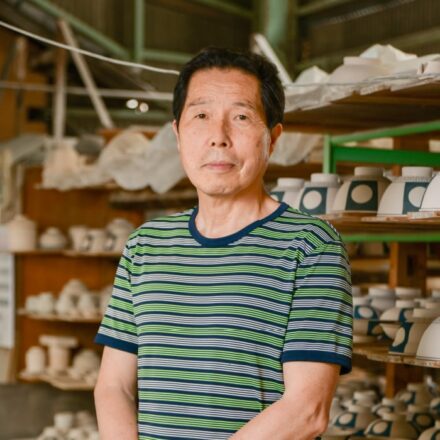

Pursuing ease of use by trial and error

After thinking deeply with Masanori, the second generation president, they came up with the “Nishiki” lidded bowl, which is painted with vivid red, gold, blue, and green colors. “After looking at a variety of dishes from all over the country and thinking about patterns, we decided to use traditional brocade, which never goes out of style,” said Masanori. There are three types of designs: Cherry blossoms, Peonies, and flowers and birds, which have been popular for a long time. He introduced copperplate transfer, which had become the mainstream method for mass-produced dyed porcelain. When the finished product was presented to a distributor, the reaction was positive. “It’s rare for a manufacturer to be able to produce a brocade bowl with such high quality”. Many restaurants began to use them. However, just as it seemed to be getting off the ground, there were problems such as the bowls were breaking easily and chipping. Restaurants use and wash the same dishes several times a day, so they need to be stronger than those for home use. In addition, they need to be easy to stack and easy to carry. The goal was to create a bowl that was strong, light and convenient to use. The first step was to review the soil from scratch. He consulted with his business partner, a clay manufacturing company, and adjusted the blend of silica and feldspar. Every time there was a problem, such as cracking or melting in the kiln, he changed the composition and firing temperature to arrive at the ideal porcelain clay. After revising the shape of the bowl many times to make it easy to stack, he finally completed a bowl that he was satisfied with. Since then, Syunzan Seito has won the trust of the public for its lidded bowls.